A five-stage, and very demanding protocol, for taking a nanoscience discovery to a consumer nanotechnology product has been outlined by engineer Michael Kelly of the University of Cambridge. Kelly, who is also based at the MacDiarmid Institute for Advanced Materials and Nanotechnology, at Victoria University of Wellington, New Zealand, explains how a clear understanding of how and why experimental silicon semiconductor and liquid crystal technology took so long to move from the laboratory bench to the manufacturing plant and mass production and consumption should underpin predictions about current nanoscience.

Kelly also explains why once a technology, such as the silicon chip, is in place it is very difficult to usurp even with advances such as conducting polymers and novel forms of carbon from buckyballs (fullerenes) and nanotubes to graphene despite the hyperbole that surrounds such novel materials. He points out that too little attention is paid to the many hurdles facing the nanoscientist hoping to be revolutionary nanotechnologist. But, his systematic protocol reveals what the aspirational need to know in making that quantum leap.

If one is working towards nanotechnology, then one must first identify the environment in which a new nanomaterial will be superior to the current state-of-the art material, otherwise the science becomes a solution looking for a problem. There are a few examples of fundamental science, the laser being a rare example, where uses are found after the fact, but, Kelly suggests that, in a burgeoning field with myriad projects and experiments final outcomes do not commonly justify the initial effort.

Secondly, it is important to identify the critical properties of the new nanomaterial and to be able to reproduce them absolutely in different samples with values to within better than 10 percent of the mean or there is no possibility of mass production. He points out that semiconductor tunnelling devices have only very recently addressed this problem.

Thirdly, a way to make the material or device with pre-specified performance and at high yield is essential from an early stage of development or again wasted raw materials will keep end product costs too high for a product to be commercially viable.

Kelly’s fourth commandment asserts that for a product, one must be able to simulate its performance from first principles and to readily invert properties at any stage of development so that it might be reverse engineered and adapted to resolve discrepancies where a device deviates from design.

Fifth and finally, even if the first four steps of the protocol are addressed adequately lifetime performance must be demonstrated as being superior to any current state-of-the art technology. He cites multi-heterojunction tandem solar cell technology as being on the cusp of serious development in this regard, one might also mention organic light emitting diodes (OLEDs) and their development from unstable devices in the early 1990s to fully fledged commercial technology today.

The shift from traditional manufacturing to the current developments based on novel and even designer materials means that industry now places great emphasis on product development taking place at the laboratory bench and expects much more than a one-off result before adopting new science and converting it into technology, nano or otherwise.

![]() Kelly M.J. (2014). From nanoscience to nanotechnology: what can and what cannot be manufactured, International Journal of Nanotechnology, 11 (5/6/7/8) 441. DOI: http://dx.doi.org/10.1504/ijnt.2014.060563

Kelly M.J. (2014). From nanoscience to nanotechnology: what can and what cannot be manufactured, International Journal of Nanotechnology, 11 (5/6/7/8) 441. DOI: http://dx.doi.org/10.1504/ijnt.2014.060563

It was almost inevitable that the naysayers and scaremongers would start to express concerns about graphene, the new wonder material that won its developers a Nobel prize for their work with sticky tape and HB pencils. It’s sensible to look at graphene if there are risks and Ken Donaldson, a respiratory toxicologist at the University of Edinburgh, and his colleagues have been among the first to raise the warning flag on graphene, at least for nanoscopic platelets of the stuff. In case you didn’t know graphene is essentially a single, monolayer, of graphite, the carbon allotrope found in soot, charcoal and, yes, the “lead” in an HB pencil.

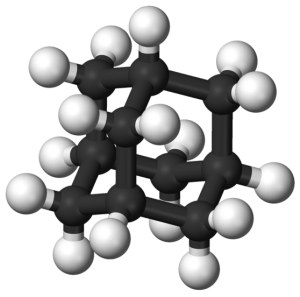

It was almost inevitable that the naysayers and scaremongers would start to express concerns about graphene, the new wonder material that won its developers a Nobel prize for their work with sticky tape and HB pencils. It’s sensible to look at graphene if there are risks and Ken Donaldson, a respiratory toxicologist at the University of Edinburgh, and his colleagues have been among the first to raise the warning flag on graphene, at least for nanoscopic platelets of the stuff. In case you didn’t know graphene is essentially a single, monolayer, of graphite, the carbon allotrope found in soot, charcoal and, yes, the “lead” in an HB pencil. Adamantane, the invincible molecule, was discovered in petroleum in 1933 and stimulated a whole new field in chemistry, that of research into polyhedral organic compounds. It might be thought of as the tiniest possible building block of diamond, which is after all an infinite 3D network of carbon atoms essentially pinned on the adamantane structure minus the hydrogens. Adamantane itself has been modified for practical applications in the pharmaceutical industry, in polymer science for heat-stable lubricants and others uses, and as molecular building blocks in nanotechnology. But, this “diamondoid” and its chemical cousins might also be the molecular mavens we need to guide hydrocarbon exploration.

Adamantane, the invincible molecule, was discovered in petroleum in 1933 and stimulated a whole new field in chemistry, that of research into polyhedral organic compounds. It might be thought of as the tiniest possible building block of diamond, which is after all an infinite 3D network of carbon atoms essentially pinned on the adamantane structure minus the hydrogens. Adamantane itself has been modified for practical applications in the pharmaceutical industry, in polymer science for heat-stable lubricants and others uses, and as molecular building blocks in nanotechnology. But, this “diamondoid” and its chemical cousins might also be the molecular mavens we need to guide hydrocarbon exploration.

Six science books for the holiday season subjects as diverse as molecular biology pioneer Sydney Brenner, the question of antimatter, how scientists can better explain their research to non-scientists, a history of the chemical elements, scientific feuds and how innovators exploit business and technology trends.

Six science books for the holiday season subjects as diverse as molecular biology pioneer Sydney Brenner, the question of antimatter, how scientists can better explain their research to non-scientists, a history of the chemical elements, scientific feuds and how innovators exploit business and technology trends. Should nanotechnology R&D be more open to allow it to thrive in the commercial world, or should companies working in this field be more secretive? Paradoxically, the answer seems to be that keeping secrets stifles innovation and reduces patent success. According to Associate Professor of Management at Pennsylvania State University Abington, Steven McMillan, companies should adopt an open policy towards publication of their R&D results as is common in research institutes, university research departments and academia in general.

Should nanotechnology R&D be more open to allow it to thrive in the commercial world, or should companies working in this field be more secretive? Paradoxically, the answer seems to be that keeping secrets stifles innovation and reduces patent success. According to Associate Professor of Management at Pennsylvania State University Abington, Steven McMillan, companies should adopt an open policy towards publication of their R&D results as is common in research institutes, university research departments and academia in general.